Frp Round Tube Pultrusion Mould

Frp Round Tube Pultrusion Mould Specification

- Life Span

- Up to 200,000 cycles

- Mould Base

- Hardened Alloy Steel

- Core Material

- High Strength Alloy

- Tolerance

- 0.05 mm

- Working Process

- Pultrusion

- Material

- FRP (Fiberglass Reinforced Plastic)

- Shaping Mode

- Extrusion Moulding

- Punch Dies

- Customizable Design

- Die Head

- Precision Ground Steel

- Application

- FRP Round Tube Manufacturing

- Hardness

- HRC 50-52

- Mould Cavity

- Single or Multi-Cavity Optional

- Cooling Type

- Water Cooling System

- Processing Speed

- High Efficiency, Up to 1.2 m/min

- Corrosion Resistance

- Excellent

- Customization

- Available upon Request

- Surface Finish

- Mirror Polished

- Dimension Range

- Customizable (as per drawing/specification)

Frp Round Tube Pultrusion Mould Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Henan

- Payment Terms

- Letter of Credit (L/C), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 20-25 Days

- Main Export Market(s)

- South America, Eastern Europe, Western Europe, Middle East, North America, Central America, Asia

- Main Domestic Market

- All India

About Frp Round Tube Pultrusion Mould

Frp Round Tube Pultrusion Mould

We are an unparalleled name in offering a wide gamut of Round Mold. This mold is manufactured and designed in adherence to set industry standard using outstanding quality material and advanced techniques by our professionals. Our offered product is widely demanded for moulding and shaping different products in different industries. In order to meet exact requirement of our client, we keep changes in our Round Mold quality as per market trend. Sturdy construction, compact size and long functional life are features of offered mold.

Precision Pultrusion for Round Tubes

Our FRP Round Tube Pultrusion Mould guarantees consistent and accurate tube production, supported by a precise shaping mode and customizable specifications. Its mirror-polished finish enhances product aesthetics, while the precision-ground steel die head promotes seamless operation and high output rates.

Efficient Cooling and Enhanced Durability

With a robust water cooling system and construction using hardened alloy steel, the mould resists corrosion and delivers prolonged performance. The high-strength alloy core material, coupled with the HRC 50-52 hardness, secures a life span of up to 200,000 cycles for industrial scale production without compromise.

Customizable for Varied Applications

Tailored to your requirements, the moulds cavity configuration and punch die design are adjustable to match specific product parameters. Its flexibility supports different tube diameters and lengths, making it a versatile tool for manufacturers, distributors, and traders catering to diverse project needs.

FAQs of Frp Round Tube Pultrusion Mould:

Q: How is the FRP round tube pultrusion mould designed to optimize tube manufacturing?

A: The mould is engineered using hardened alloy steel and high-strength alloys for the core to ensure durability and precision. Its single or multi-cavity options, mirror-polished surface, and 0.05 mm tolerance enhance tube quality, while the water cooling system sustains high processing efficiency.Q: What customization options are available for the moulds dimensions and cavity structure?

A: Dimensions and cavity structures are fully customizable based on your specific drawings or specifications. Both single and multi-cavity designs can be selected, and punch dies may also be tailored to suit your individual production requirements.Q: When should the mould be serviced or replaced during the production cycle?

A: The mould is built to withstand up to 200,000 production cycles, depending on operational conditions and maintenance practices. Regular inspections and maintenance are recommended to ensure optimal performance and extend its service life.Q: Where is the FRP round tube pultrusion mould most commonly used?

A: This mould is predominantly utilized in industries involved in the manufacturing, distribution, export, and supply of FRP round tubes. Its precision and efficiency have made it popular among manufacturers and traders in China and worldwide.Q: What is the pultrusion process and how does it benefit FRP tube production?

A: Pultrusion is a continuous extrusion moulding process wherein fiberglass reinforced plastic is drawn through a heated die to form tubes. It delivers high efficiency, consistent dimensional accuracy, and superior surface finish, making it ideal for producing large quantities of FRP round tubes.Q: How does the water cooling system contribute to the moulds performance?

A: The integrated water cooling system ensures rapid heat dissipation during the pultrusion process, allowing for high processing speeds (up to 1.2 m/min) and preventing thermal damage. This enhances product consistency and prolongs mould life in demanding manufacturing environments.Q: What are the main advantages of using this FRP round tube pultrusion mould in tube production?

A: Key benefits include high processing speed, excellent dimensional accuracy, outstanding corrosion resistance, and long mould lifespan. Its customizable design and precision ensure reliable, efficient, and aesthetically pleasing FRP round tube production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Pultrusion Die And Molds Category

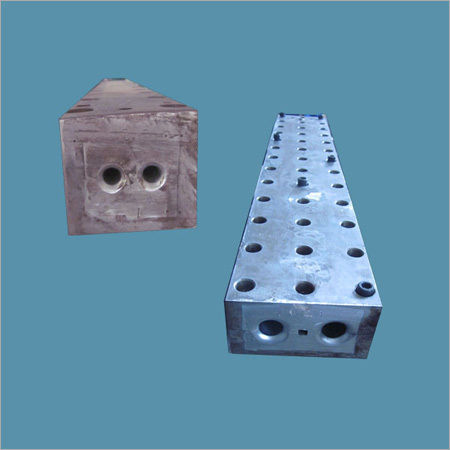

Two Cavity Mold

Price 2000 USD ($) / Set

Minimum Order Quantity : 1 Set

Core Material : Hardened Steel

Shaping Mode : Other, Injection Mould

Life Span : 100,000 shots

Material : Other, Plastic/Steel

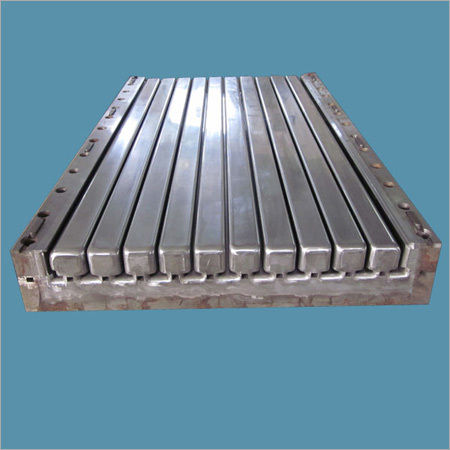

Stair Tread Mold

Price 6000 USD ($) / Set

Minimum Order Quantity : 1 Set

Core Material : P20/NAK80/S136 Steel

Shaping Mode : Other, Injection Mould

Life Span : 500,0001,000,000 shots

Material : Other, Plastic/Metal

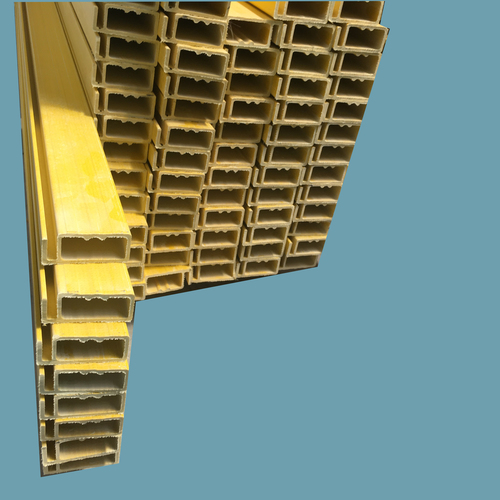

Yellow Channel

Price 1 USD ($) / Meter

Minimum Order Quantity : 1 Meter

Core Material : H13 Steel

Shaping Mode : Extrusion Mould

Life Span : 5,00,000 Shots

Material : Other, Plastic / PVC

Epoxy Rod Pultrusion Die

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Core Material : HighSpeed Steel (HSS)

Shaping Mode : Other, Pultrusion

Life Span : Above 100,000 uses

Material : Other, Tool Steel, Alloy Steel, Stainless Steel

Send Inquiry

Send Inquiry