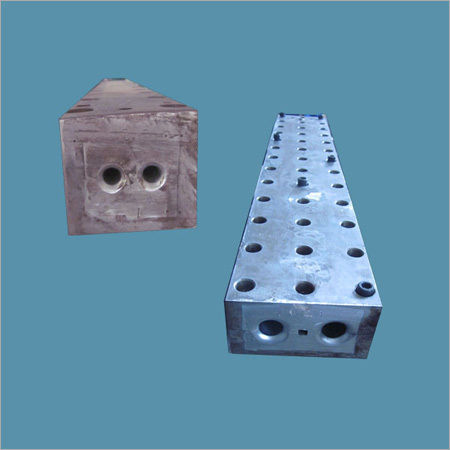

Two Cavity Mold

Two Cavity Mold Specification

- Tolerance

- 0.01 mm

- Working Process

- CNC Machining, EDM, Grinding

- Life Span

- 100,000 shots

- Core Material

- Hardened Steel

- Mould Base

- Steel

- Material

- Plastic/Steel

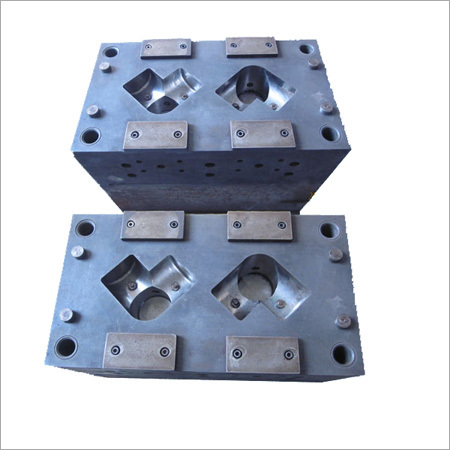

- Shaping Mode

- Injection Mould

- Punch Dies

- Interchangeable, Wear-resistant

- Die Head

- Precision Finished

- Ejection System

- Pin Ejector

- Design Software

- UG, Pro/E, SolidWorks, AutoCAD

- Runner System

- Cold/Hot Runner Available

- Application

- Plastic Injection Molding

- Cavity Number

- 2

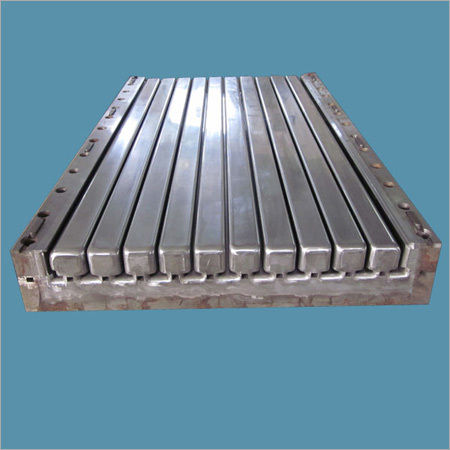

- Mould Surface

- Mirror Polish/Texture

- Cycle Time

- Fast Cycle Time

- Gate Type

- Pin Point/Sub Gate

- OEM Service

- Available

- Mould Size

- Customized

Two Cavity Mold Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Henan

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cheque

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 20-25 Days

- Main Export Market(s)

- Western Europe, North America, Eastern Europe, Middle East, South America, Asia

- Main Domestic Market

- All India

About Two Cavity Mold

Two Cavity Mold

Having a definite quality management system, we are regarded as the noteworthy name engaged in offering of an enhanced quality Two Cavity Mold. This cavity mold is precisely engineered and designed by our very knowledgeable professionals using quality approved material and advanced techniques that are facilitated in our huge manufacturing unit. We offer this Two Cavity Mold after assuring its quality on different stages to achieve the satisfaction and trust of our customers. Abrasion resistance, easy to maintain and accurate dimension are features of offered cavity mold.

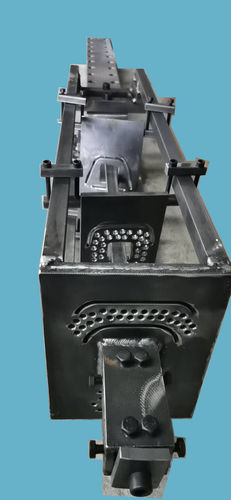

Tailored Solutions for Plastic Injection Molding

Our Two Cavity Mold is engineered for versatility and efficiency, supporting both cold and hot runner systems. With a fast cycle time and durable steel mould base, it is suitable for a variety of plastic applications. Mirror polish or textured surfaces ensure excellent finish options, while precision CNC, EDM, and grinding processes guarantee consistent, high-quality results. OEM and customization options are available to meet your specific manufacturing needs.

Benefits of Precision Manufacturing

Utilizing advanced design software and interchangeably wear-resistant punch dies, this mold promises prolonged life and maintenance ease. The steel construction enhances durability against high-volume cycles, while pin point and sub gate choices offer flexibility for diverse parts. Each mold is crafted to strict tolerances, ensuring repeatable accuracy and reliable production.

FAQs of Two Cavity Mold:

Q: How is the Two Cavity Mold customized to meet different production requirements?

A: The mold size, surface finish, runner system, and gate type can be tailored to your specifications. You can choose between mirror polish or texture for mould surfaces, select cold or hot runners, and specify mold dimensions according to your part design. OEM services also allow further customization for unique applications.Q: What is the process for manufacturing the Two Cavity Mold?

A: The mold is manufactured using CNC machining, EDM, and grinding. Design files are created with UG, Pro/E, SolidWorks, or AutoCAD, ensuring precision. The core material is hardened steel, and every mold undergoes precision finishing, including interchangeable punch dies, making it wear-resistant and maintaining tight tolerances.Q: When should I use a hot runner versus a cold runner system for this mold?

A: Hot runner systems are beneficial for reducing waste and cycle time, especially in high-volume production, while cold runner systems may be preferable for simpler, lower-cost applications or when processing temperature-sensitive materials. Your choice should depend on your process requirements and production scale.Q: Where is this Two Cavity Mold typically used?

A: This mold is widely used in precision plastic injection molding, commonly in industries such as automotive, consumer goods, electronics, and medical devices. Its applications extend to any plastic part production requiring fast cycle times and high repeatability.Q: What advantages does the pin ejector ejection system provide?

A: The pin ejector system ensures reliable and consistent ejection of molded parts, minimizing defects and cycle interruptions. It is especially effective when handling complex or delicate shapes, aiding in smooth part removal without causing damage.Q: How does the molds life span and wear-resistance benefit users?

A: With a hardened steel core and interchangeable wear-resistant punch dies, the mold offers a lifespan up to 100,000 shots. This reduces maintenance frequency and ensures sustained accuracy and performance throughout extensive production runs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Pultrusion Die And Molds Category

Frp Tube Mould

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Shaping Mode : Other, Compression moulding

Punch Dies : Corrosionresistant alloy

Mould Base : Highstrength steel

Frp Round Tube Pultrusion Mould

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Shaping Mode : Other, Extrusion Moulding

Punch Dies : Customizable Design

Mould Base : Hardened Alloy Steel

Stair Tread Mold

Price 6000 USD ($) / Set

Minimum Order Quantity : 1 Set

Shaping Mode : Other, Injection Mould

Punch Dies : Precision Hardened Steel

Mould Base : Steel

FRP Tube Elbow Mold

Price Range 3500.00 - 8000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Shaping Mode : Other, Casting Mold

Punch Dies : Hardened Alloy Steel

Mould Base : Stainless Steel

Send Inquiry

Send Inquiry