Epoxy Rod Pultrusion Die

Epoxy Rod Pultrusion Die Specification

- Mould Base

- Stainless Steel

- Tolerance

- 0.02 mm

- Life Span

- Above 100,000 uses

- Core Material

- High-Speed Steel (HSS)

- Working Process

- CNC Machining, Polishing, Grinding

- Material

- Tool Steel, Alloy Steel, Stainless Steel

- Shaping Mode

- Pultrusion

- Punch Dies

- Precision Fabricated

- Die Head

- Heat-treated Alloy Steel

- Application

- Industrial Pultrusion Processes

- Maintenance

- Low, easy to dismantle and clean

- Die Opening Type

- Manual/Automatic

- Dimension

- Customizable per requirement

- Production Capacity

- 300-500 rods/day

- Surface Finish

- Mirror Polished

- Heat Resistance

- Up to 350°C

- Suitable For

- Epoxy/Fiberglass Rod Production

- Cooling System

- Integrated Water Cooling Channel

- Corrosion Resistance

- High

Epoxy Rod Pultrusion Die Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Henan

- Payment Terms

- Telegraphic Transfer (T/T), Paypal, Letter of Credit (L/C), Western Union, Cheque

- Supply Ability

- 100 Sets, , Per Month

- Delivery Time

- 20-25 Days

- Main Domestic Market

- All India

About Epoxy Rod Pultrusion Die

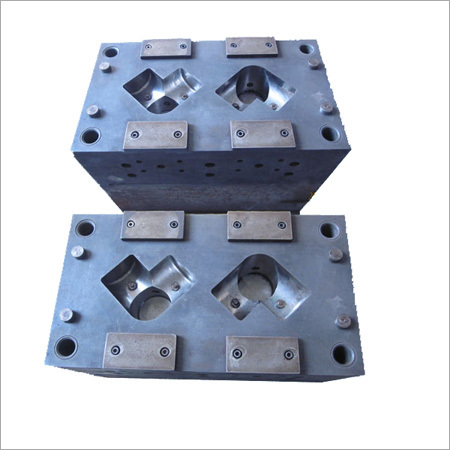

Epoxy Rod Pultrusion Die

We have emerged as the prominent name engaged in offering of supreme quality Epoxy Rod Pultrusion Die. This die is manufactured and designed by our experienced professionals in adherence with market quality standards from optimum grade materials and progressive technology. The pultrusion die offered by us widely used in electronics and automobile industry. Our offered Epoxy Rod Pultrusion Die is known in the market for its sturdiness, accurate dimension, corrosion resistance, etc. Moreover, we provide this pultrusion die in varied specifications.

Advanced Design for Industrial Pultrusion

Our Epoxy Rod Pultrusion Die is the result of meticulous engineering and advanced manufacturing processes. Heat-treated alloy steel die heads and precision fabricated punch dies guarantee uniform rod shaping and high durability. Integrated water cooling channels efficiently dissipate heat, maintaining die integrity even under continuous operation. The customizable dimension options let you tailor the die to specific project requirements, ensuring compatibility across varied industrial applications.

Efficiency and Reliability in Production

With a capacity of 300500 rods per day and a lifespan exceeding 100,000 uses, this pultrusion die offers both productivity and longevity. The low-maintenance, easy-to-dismantle design significantly reduces downtime, while the combination of corrosion-resistant stainless steel and high-speed steel core provides robust performance in harsh industrial environments.

FAQs of Epoxy Rod Pultrusion Die:

Q: How does the integrated water cooling channel benefit the pultrusion process?

A: The integrated water cooling channel helps regulate the dies temperature during continuous rod production, preventing overheating and thermal deformation. This ensures consistent rod quality, prolongs die lifespan, and maintains operational efficiency in high-output industrial environments.Q: What materials is the Epoxy Rod Pultrusion Die constructed from?

A: The die features a stainless steel mould base, a heat-resistant high-speed steel core, heat-treated alloy steel die head, and precision fabricated punch dies made from tool steel, alloy steel, and stainless steel. These materials ensure durability, corrosion resistance, and heat tolerance up to 350C.Q: When should the die be dismantled for maintenance, and how easy is the process?

A: Regular inspection is recommended after every 5,000 uses, or sooner in highly demanding settings. The die is designed for easy dismantling and cleaning, minimizing downtime and making maintenance straightforward for production teams.Q: Where is this pultrusion die commonly used, and in which industries?

A: The Epoxy Rod Pultrusion Die is widely utilized in industrial environments that manufacture epoxy or fiberglass rods, such as construction, electrical insulation, and composite material industries. It is suitable for manufacturers, exporters, and suppliers based in China or serving the global market.Q: What pultrusion process steps does this die accommodate?

A: This die supports pultrusion steps involving CNC machining, polishing, and grinding, as well as shaping and thermal management through its integrated cooling system. Both manual and automatic die opening options are available, offering flexibility in production workflow.Q: How does the mirror-polished surface affect the finished rods?

A: A mirror-polished die surface reduces friction and material adhesion, resulting in rods with smoother finishes and higher structural integrity. This also aids in easier cleaning and maintenance of the die.Q: What is the primary benefit of using this die for rod production?

A: The primary benefit is its combination of efficiency and precision delivering high daily output, exceptional dimensional tolerance (0.02 mm), and reliability. The durable construction materials extend the dies life cycle, which collectively help reduce operational costs and boost production quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in FRP Pultrusion Die And Molds Category

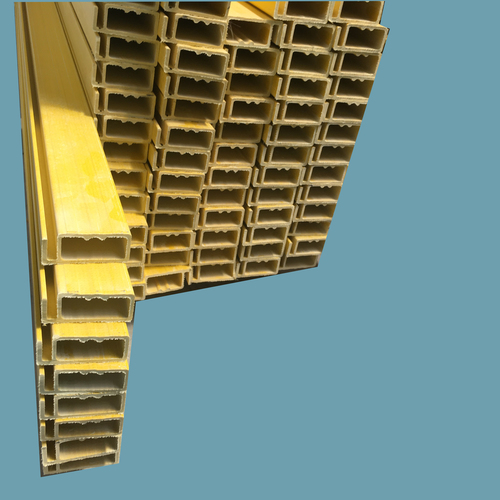

Yellow Channel

Price 1 USD ($) / Meter

Minimum Order Quantity : 1 Meter

Material : Other, Plastic / PVC

Punch Dies : Precision Ground

Mould Base : P20 Steel

Frp Round Tube Pultrusion Mould

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Other, FRP (Fiberglass Reinforced Plastic)

Punch Dies : Customizable Design

Mould Base : Hardened Alloy Steel

Panel Mould

Price 6000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Other, Plastic, Metal

Punch Dies : Precision Engineered

Mould Base : Hardened Steel

FRP Tube Elbow Mold

Price Range 3500.00 - 8000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Other, FRP (Fiberglass Reinforced Plastic)

Punch Dies : Hardened Alloy Steel

Mould Base : Stainless Steel

Send Inquiry

Send Inquiry