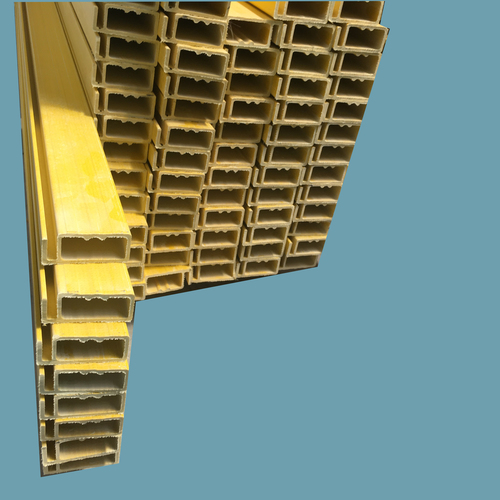

Yellow Channel

Yellow Channel Specification

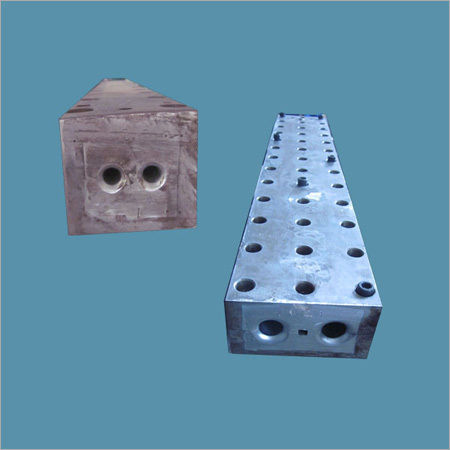

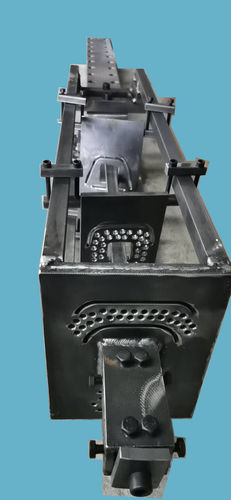

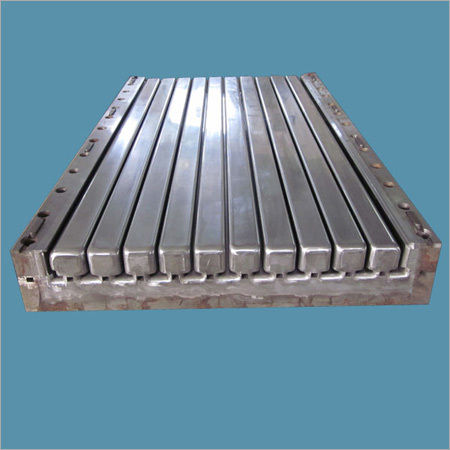

- Working Process

- EDM, Milling, Grinding

- Tolerance

- 0.01 mm

- Mould Base

- P20 Steel

- Life Span

- 5,00,000 Shots

- Core Material

- H13 Steel

- Material

- Plastic / PVC

- Shaping Mode

- Extrusion Mould

- Punch Dies

- Precision Ground

- Die Head

- Single Cavity

- Height

- 10 mm

- Surface Finish

- Smooth

- Length

- 2 Meters (Standard)

- Color

- Yellow

- Width

- 20 mm

- Application

- Cable Management, Wiring Channels

Yellow Channel Trade Information

- Minimum Order Quantity

- 1 Meter

- FOB Port

- Henan

- Payment Terms

- Telegraphic Transfer (T/T), Paypal, Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Cheque

- Supply Ability

- 10000 Meters Per Month

- Delivery Time

- 20-25 Days

- Main Export Market(s)

- Western Europe, Eastern Europe, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About Yellow Channel

Owing to our vast industrial experience in this domain, we are engaged in offering wide assortment of Yellow Channel. This product is manufactured and designed with the help of outstanding quality material and advanced machines that are installed in our manufacturing unit. Our offered channel is made available in number of technical specifications as per the emerging demands of our clients. Our offered Yellow Channel can avail by our clients at market leading rates. Sturdy construction, compact size and easy to install are features of offered product.

Versatile Cable Management Solution

The Yellow Channel ensures efficient organization of electrical wiring in commercial, industrial, and residential settings. Its standardized dimensions and smooth finish make it easy to install, while its bright yellow color enhances visibility. This channel is ideal for keeping cables tidy and protected in areas requiring reliable wiring infrastructure.

Advanced Manufacturing and Durability

Produced with extrusion molding and precision-ground dies, the Yellow Channel benefits from the use of P20 steel for the mould base and H13 steel for the core, ensuring resilience and longevity. Its tolerance up to 0.01 mm guarantees consistent quality, and the product is built to last through 500,000 shots, providing dependable performance over the years.

FAQs of Yellow Channel:

Q: How is the Yellow Channel installed for cable management?

A: The Yellow Channel can be easily affixed to walls or surfaces using screws or adhesive strips. Its standard size and lightweight PVC composition allow for quick and straightforward installation in a variety of environments.Q: What makes the Yellow Channel suitable for wiring applications?

A: Engineered from high-grade Plastic/PVC and precision-manufactured for consistency, the Yellow Channel offers effective protection and organization for wiring. Its smooth finish helps prevent cable abrasion, and its bright color aids in easy identification during maintenance.Q: When should I use this cable management channel?

A: The Yellow Channel is best used during electrical installations, refurbishments, or whenever you need organized cable routing in commercial, industrial, or residential spaces. It is especially practical where visibility and orderliness are priorities.Q: Where can I purchase the Yellow Channel?

A: You can acquire the Yellow Channel through authorized distributors, exporters, suppliers, and traders in China. Many of these partners facilitate both bulk and retail orders for local and international customers.Q: What is the manufacturing process behind the Yellow Channel?

A: The Yellow Channel is produced using extrusion moulding, combined with EDM, milling, and grinding for precision. Mould bases are constructed from P20 steel and cores from H13 steel, employing a single cavity die and precision-ground punches for high accuracy.Q: What benefits does the Yellow Channel offer over traditional channels?

A: This product provides high durability, excellent dimensional accuracy, easy handling, and visibility owing to its vibrant color. Its smooth finish and robust construction ensure lasting performance and simplified maintenance for your cable management needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Pultrusion Die And Molds Category

Two Cavity Mold

Price 2000 USD ($) / Set

Minimum Order Quantity : 1 Set

Core Material : Hardened Steel

Punch Dies : Interchangeable, Wearresistant

Life Span : 100,000 shots

Mould Base : Steel

Frp Tube Mould

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Core Material : Fiberglassreinforced plastic (FRP)

Punch Dies : Corrosionresistant alloy

Life Span : Up to 5 years (depending on usage)

Mould Base : Highstrength steel

Stair Tread Mold

Price 6000 USD ($) / Set

Minimum Order Quantity : 1 Set

Core Material : P20/NAK80/S136 Steel

Punch Dies : Precision Hardened Steel

Life Span : 500,0001,000,000 shots

Mould Base : Steel

Panel Mould

Price 6000 USD ($) / Set

Minimum Order Quantity : 1 Set

Core Material : HighGrade Steel

Punch Dies : Precision Engineered

Life Span : Up to 500,000 shots

Mould Base : Hardened Steel

Send Inquiry

Send Inquiry