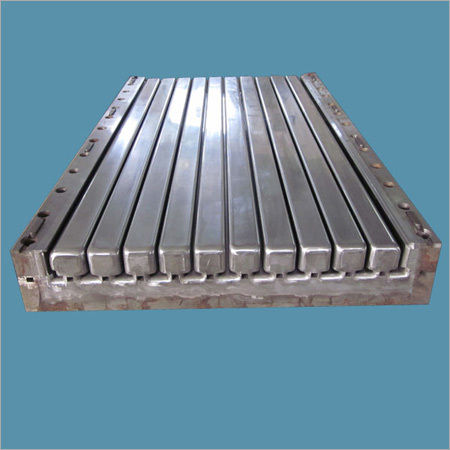

Stair Tread Mold

Stair Tread Mold Specification

- Mould Base

- Steel

- Tolerance

- 0.01 mm

- Working Process

- CNC Machining, EDM, Milling, Polishing

- Life Span

- 500,000-1,000,000 shots

- Core Material

- P20/NAK80/S136 Steel

- Material

- Plastic/Metal

- Shaping Mode

- Injection Mould

- Punch Dies

- Precision Hardened Steel

- Die Head

- Customizable As Per Drawing

- Application

- Staircase Step Tread Production

- Cavity

- Single/Multiple

- Runner System

- Hot/Cold Runner Optional

- Design Software

- UG, Pro/E, AutoCAD

- Color

- Custom

- OEM Service

- Available

- Mould Surface

- Mirror Polish, Texture Finish

- Processing Type

- Custom Molding

- Mould Size

- Up To 3000 mm

Stair Tread Mold Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Henan

- Payment Terms

- Letter of Credit (L/C), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 20-25 Days

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, South America, Asia

- Main Domestic Market

- All India

About Stair Tread Mold

Stair Tread Mold

Our organization has successfully expanded its business in market owing to the given elevated quality assortment of Stair Tread Mold. This mold is made in our high-tech manufacturing unit under the guidance of our skilled supervisor using outstanding quality material. In order to give flawless product range, we keep a strict vision on every product of production process and assure its quality till finish. In addition to this, clients can avail this Stair Tread Mold from us at pocket friendly price.

Advanced Runner System for Efficiency

Choose between hot and cold runner systems to optimize your manufacturing process and reduce cycle times. The molds adaptable runner system supports various production needs, enhancing material flow and energy efficiency during tread formation.

Cutting-edge Design Software Integration

Designs are meticulously created using industry-leading CAD software including UG, Pro/E, and AutoCAD, ensuring accuracy and tailored fit for diverse architectures. This advanced integration aids in precise modeling, quick prototyping, and efficient production adjustments.

Durable Materials and Superior Finish

Built on a solid steel mold base with high-quality core materials like P20, NAK80, or S136, our mold offers both mirror polish and textured finishes. These options provide not just aesthetic appeal but also functional traction and durability for high-traffic stairways.

FAQs of Stair Tread Mold:

Q: How is the Stair Tread Mold with Runner System customized for various projects?

A: Customization is available for mold dimensions, cavity numbers, surface finishes, colors, and die head specifications. OEM services and personalized shaping ensure precise results tailored to client drawings and staircase requirements.Q: What materials are used for the mold core and base, and what benefit do they offer?

A: The mold core is made from P20, NAK80, or S136 steel, while the base is constructed from sturdy steel. These materials provide exceptional durability, heat resistance, and extend the mold lifespan to 500,0001,000,000 shots.Q: When is the hot or cold runner system chosen for stair tread production?

A: Hot runner systems are preferred for high-volume, continuous production to improve efficiency and reduce waste, while cold runner options suit lower-volume or cost-sensitive projects. The choice depends on production scale and material requirements.Q: Where is the Stair Tread Mold typically used?

A: This mold is used in industrial settings for manufacturing staircase step treads across commercial and residential construction projects. It is widely adopted by manufacturers, distributors, exporters, and suppliers throughout China and internationally.Q: What is the manufacturing process involved for this mold?

A: Every mold undergoes CNC machining, EDM, milling, polishing, and meticulous quality checks. These advanced processes yield precise tolerances of 0.01 mm and high-quality mirror or textured finishes for each tread produced.Q: How does using this stair tread mold benefit production operations?

A: Utilizing this mold increases product consistency, reduces manufacturing time, and ensures high-precision tread shapes. The robust runner system and superior materials contribute to lower maintenance needs and extended mold life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Pultrusion Die And Molds Category

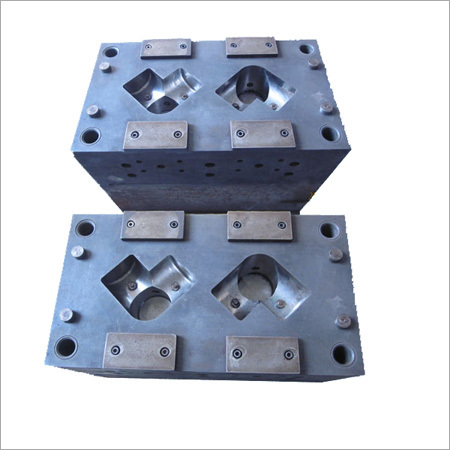

FRP Tube Elbow Mold

Price Range 3500.00 - 8000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Die Head : Precision Machined Steel

Material : Other, FRP (Fiberglass Reinforced Plastic)

Shaping Mode : Other, Casting Mold

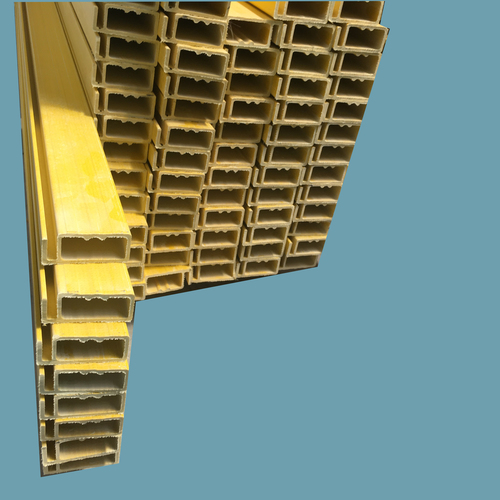

Yellow Channel

Price 1 USD ($) / Meter

Minimum Order Quantity : 1 Meter

Die Head : Single Cavity

Material : Other, Plastic / PVC

Shaping Mode : Extrusion Mould

Two Cavity Mold

Price 2000 USD ($) / Set

Minimum Order Quantity : 1 Set

Die Head : Precision Finished

Material : Other, Plastic/Steel

Shaping Mode : Other, Injection Mould

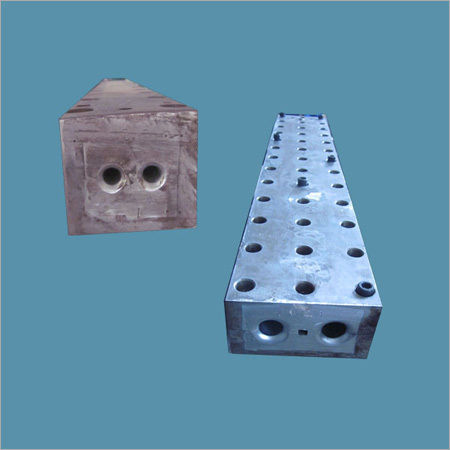

Epoxy Rod Pultrusion Die

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Die Head : Heattreated Alloy Steel

Material : Other, Tool Steel, Alloy Steel, Stainless Steel

Shaping Mode : Other, Pultrusion

Send Inquiry

Send Inquiry