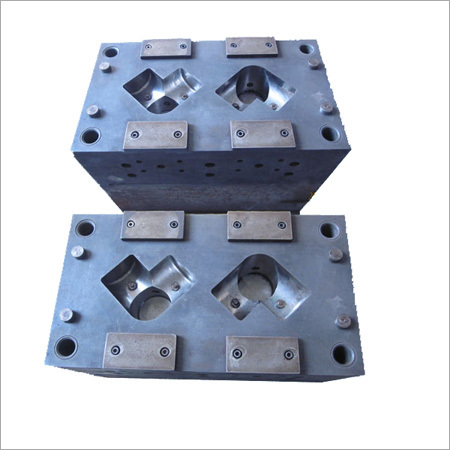

FRP Tube Elbow Mold

FRP Tube Elbow Mold Specification

- Core Material

- High-Strength Fiberglass Reinforced Plastic

- Life Span

- Up to 10 Years

- Working Process

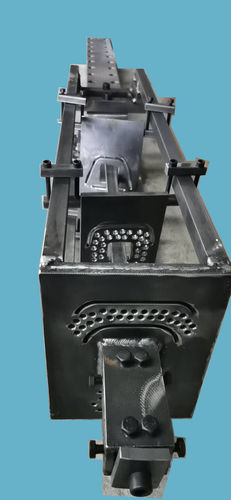

- Hand Lay-Up and Compression Molding

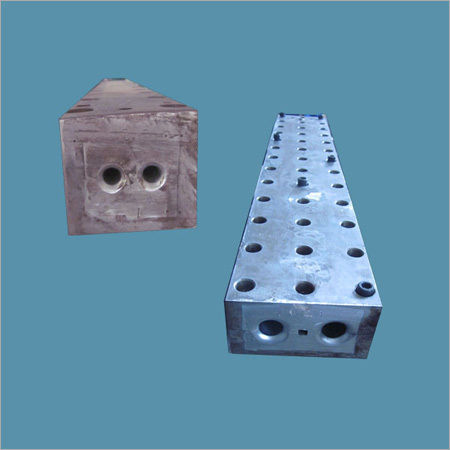

- Mould Base

- Stainless Steel

- Tolerance

- 0.2 mm

- Material

- FRP (Fiberglass Reinforced Plastic)

- Shaping Mode

- Casting Mold

- Punch Dies

- Hardened Alloy Steel

- Die Head

- Precision Machined Steel

- Production Capacity

- Customizable

- Corrosion Resistance

- Excellent

- Operating Temperature

- -40°C to 120°C

- Surface Finish

- Smooth, Polished

- Maintenance

- Low

- Compatibility

- Suitable for Various Tube Diameters

- Mold Cavity

- Single Cavity

- Color

- Standard Grey or Custom

- Application

- Manufacture of Tube Elbow Fittings

- Mold Hardness

- HRC 45-50

- Weight

- Depends on Design (Typically 20-50 kg)

FRP Tube Elbow Mold Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Henan

- Payment Terms

- Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit at Sight (Sight L/C)

- Supply Ability

- 30 Sets, , Per Month

- Delivery Time

- 20-25 Days

- Main Export Market(s)

- Central America, North America, South America, Middle East, Asia

- Main Domestic Market

- All India

About FRP Tube Elbow Mold

FRP Tube Elbow Mold

Excellent Corrosion Resistance and Longevity

Built with high-strength FRP and a stainless steel base, this mold offers superior corrosion resistance, ensuring reliability in harsh environments. Rated for a service life of up to 10 years, it supports long-term, consistent manufacturing routines for a wide range of tube elbow fittings without frequent replacement or high maintenance costs.

Adaptable Production for Custom Applications

The FRP Tube Elbow Mold offers customizable production capacity and supports various tube diameters. Its single-cavity design ensures precision, while the working processcombining hand lay-up and compression moldingallows manufacturers to meet custom requirements efficiently. This adaptability makes it suitable for many industry sectors, from plumbing to industrial piping.

Precision Engineering for Quality Fittings

Featuring advanced die heads, hardened alloy steel punch dies, and a polished surface finish, the mold guarantees tight tolerances of 0.2 mm. Its robust composition prevents deformation, while ensuring tube elbows are manufactured with consistent, smooth surfaces and reliable mechanical properties for optimal system performance.

FAQs of FRP Tube Elbow Mold:

Q: How is the FRP Tube Elbow Mold used in manufacturing tube elbow fittings?

A: The mold serves as a form in which fiberglass reinforced plastic is shaped into tube elbow fittings using hand lay-up and compression molding processes. These methods ensure a smooth, polished finish and precise dimensions for high-quality components.Q: What advantages does the FRP material offer for this mold?

A: FRP provides excellent durability, corrosion resistance, and strength. It reduces maintenance needs, supports a lifespan of up to 10 years, and maintains performance under temperatures ranging from -40C to 120C, making it ideal for industrial settings.Q: When should I choose a customizable production capacity for my tube elbow mold?

A: Customizable production capacity is appropriate when you need to manufacture tube elbows in various sizes or quantities. This flexibility allows adaptation to specific project requirements, industry standards, or unique customer orders.Q: Where is the FRP Tube Elbow Mold typically utilized?

A: This mold is widely used in manufacturing facilities for producing tube elbow fittings used in plumbing, industrial piping, and infrastructure projects. Its available from distributors, exporters, manufacturers, suppliers, and traders, especially in China.Q: What process steps are involved when working with this mold?

A: Manufacturing involves setting up the mold, applying the FRP material using hand lay-up, followed by compression molding. The process employs precision-machined die heads and hardened alloy steel punch dies to produce accurately shaped tube elbows.Q: What are the maintenance requirements for the FRP Tube Elbow Mold?

A: The mold requires minimal maintenance due to its high corrosion resistance and robust construction. Regular inspection and cleaning are suggested to ensure optimal performance over its lifespan, but extensive servicing is rarely needed.Q: How does this mold benefit manufacturers and end-users?

A: Manufacturers benefit from the molds precision, low maintenance, long lifespan, and adaptability to various tube diameters. End-users receive superior-quality tube elbows with excellent surface finish, strength, and reliable performance in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Pultrusion Die And Molds Category

Panel Mould

Price 6000 USD ($) / Set

Minimum Order Quantity : 1 Set

Working Process : Other, Injection Moulding

Life Span : Up to 500,000 shots

Mould Base : Hardened Steel

Die Head : Multicavity design

Frp Tube Mould

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Working Process : Other, Pultrusion

Life Span : Up to 5 years (depending on usage)

Mould Base : Highstrength steel

Die Head : Alloy steel, precision manufactured

Two Cavity Mold

Price 2000 USD ($) / Set

Minimum Order Quantity : 1 Set

Working Process : Other, CNC Machining, EDM, Grinding

Life Span : 100,000 shots

Mould Base : Steel

Die Head : Precision Finished

Epoxy Rod Pultrusion Die

Price 1 USD ($) / Set

Minimum Order Quantity : 1 Set

Working Process : Other, CNC Machining, Polishing, Grinding

Life Span : Above 100,000 uses

Mould Base : Stainless Steel

Die Head : Heattreated Alloy Steel

Send Inquiry

Send Inquiry